Control Reliable Hydraulic Safety Valves

Since 2006, Control Reliable Hydraulic Safety Valves (formally Sidener Hydraulic Safety Valves) have incorporated the latest technologies and leveraged the latest safety standards to help machines run safer with increased productivity. The valves offer redundant, control reliable solenoid valves which permit the use of “Alternative Methods” according to the lockout/tagout standard. Cat. 3 PLd configurations are redundant so if there is a failure to one channel, the second channel will reliably perform the safety function.

| Control Reliable Hydraulic Safety Valves are used where ever hydraulic safety is a concern. These applications may include: | |||

|

|

|

|

Two Types of Hydraulic Safety Valves Available to

Cover all Your Safety Application Needs

Energy Isolation ValveControl Reliable’s Energy Isolation Valve functions as a two position 3-way hydraulic valve with redundant valving elements and redundant monitoring. The purpose of the valve is to, when energized, provide a flow path for a flow of hydraulic fluid from its source to the hydraulic system. When de-energized, the valve blocks flow from the hydraulic energy source and vents the hydraulic system to tank. |

|

Control Reliable Energy Isolation Valve Machine Sample

|

Blocking ValveControl Reliable’s Blocking Valve functions as a two position 2-way hydraulic valve with redundant valving elements and redundant monitoring. The purpose of the valve is to block flow in a hydraulic system. |

|

Control Reliable Blocking Valve Machine Sample

|

FAQ

Q: What is Control Reliablitiy?

A: Control Reliability essentially states that the safety system be designed, constructed and installed such that the failure of a single component within the device or system should not prevent normal machine stopping action from taking place, but shall prevent a successive machine cycle from being initiated until the failure is corrected. To achieve “Control Reliability”, a device should feature both redundancy and fault detection.

Q: What is a hydraulic safety valve?

A: A safety valve, as it pertains to fluid power, is a component that, when properly applied, can allow access to an otherwise hazardous area. This is achieved by isolating the hydraulic source away from the system and venting any residual system pressure, downstream from the valve, to tank.

Q: How does a safety valve work?

A: During normal operation, the valve operates like a traditional 3-way. If either of the redundant elements malfunction, the safety PLC or safety relay, monitoring the state of the redundant switches, will command the valve to its safe condition.

Q: What are 3 different types of hydraulic valves?

A: The three different configurations of Control Reliable Safety Valves are 2-way for blocking applications, 3-way for block and bleed applications, and LOTO or Lockout/Tagout.

Q: What is the difference between a relief and safety valve?

A: A relief valve is a device that limits the maximum pressure in a system. It does help to keep a system and its surrounding environment safe from catastrophic failures due to over-pressurization but it is not a true safety product. The safety valves that we refer to are redundantly monitored devices that meet the rigorous requirements of safety standards organizations such as ANSI and ISO.

Q: What is a hydraulic blocking valve?

A: A blocking valve, as it pertains to fluid power, is a component that, when properly applied, can allow access to an otherwise hazardous area. This is achieved by isolating the hydraulic source away from the system.

Q: How does a blocking valve work?

A: During normal operation, the valve operates like a traditional 2-way. If either of the redundant elements malfunction, the safety PLC or safety relay monitoring the state of the redundant switches will command the valve to its safe condition.

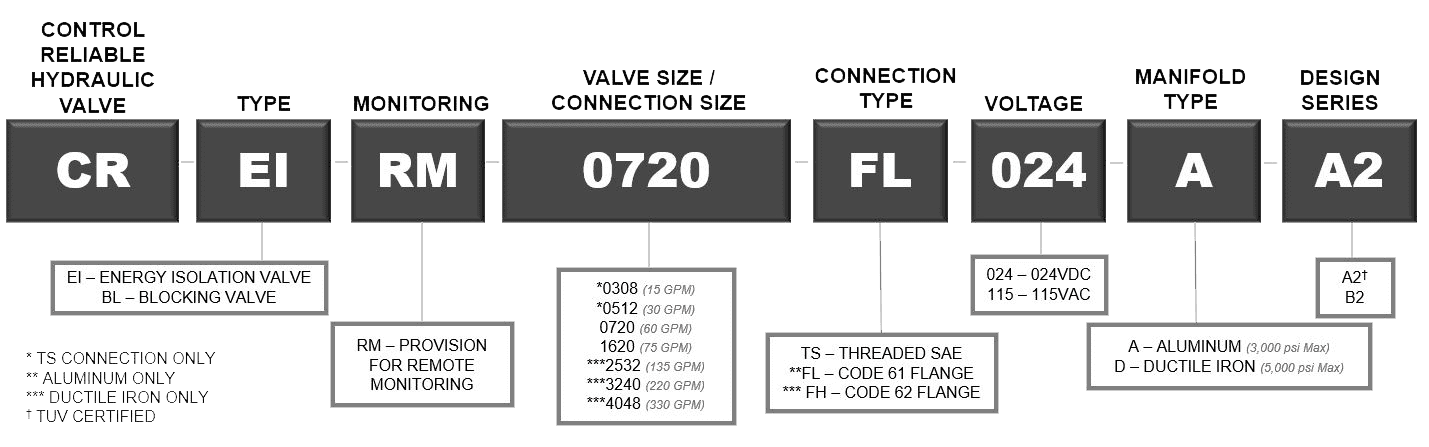

Control Reliable Hydraulic Safety Valve Specification Sheets & CAD Files

Available Upon Request