Compressed Air Dryers

An air dryer is essential for any compressed air system. Water accounts for up to 99% of total liquid contamination found in a compressed air system. Water vapor is water in gaseous form and will pass through water separators and coalescing filters just as easy as the compressed air. Water vapor left in a system can lead to corrosion, equipment malfunction, product quality issues and system failure. Parker offers a comprehensive range of compressed air dryers designed to meet the needs of customers across a variety of industries.

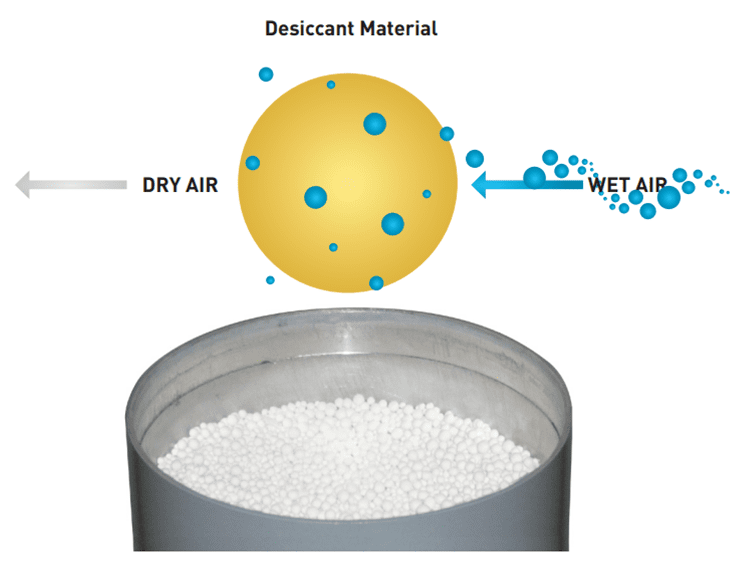

Adsorption dryers are commonly employed to dry compressed air when pressure dewpoint’s below freezing and / or the control of micro-organism growth is required. CDAS / OFAS dryers are heatless adsorption dryers, i.e. the regeneration cycle (purge cycle) uses clean, dry purge air to ensure that moisture is fully removed from the off-line desiccant bed prior to re-pressurization and being brought back on-line. As there is a cost to generate compressed air, the energy consumed by the CDAS / OFAS dryer comes from the regeneration air (purge air) it uses to regenerate the off-line desiccant bed.

Adsorption dryers are commonly employed to dry compressed air when pressure dewpoint’s below freezing and / or the control of micro-organism growth is required. CDAS / OFAS dryers are heatless adsorption dryers, i.e. the regeneration cycle (purge cycle) uses clean, dry purge air to ensure that moisture is fully removed from the off-line desiccant bed prior to re-pressurization and being brought back on-line. As there is a cost to generate compressed air, the energy consumed by the CDAS / OFAS dryer comes from the regeneration air (purge air) it uses to regenerate the off-line desiccant bed.

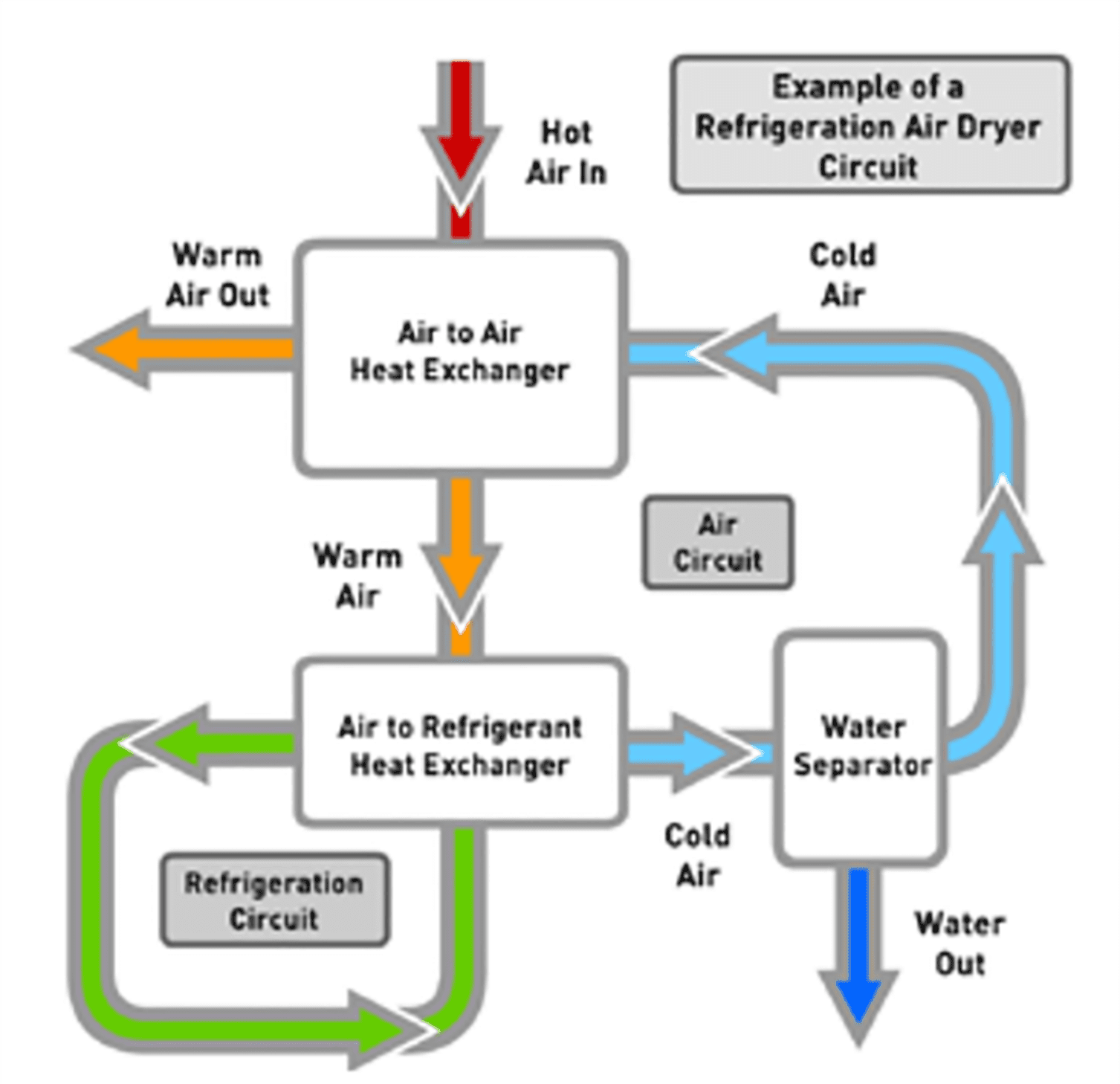

Refrigeration dryers work by cooling the air, so are limited to positive pressure dewpoint ratings to prevent freezing of the condensed liquid. Ideal for general purpose application, they typically provide pressure dewpoints of 38°F (3°C), 45°F (7°C) or 50°F (10°C) pdp. Air is reheated before it re-enters the system to prevent piping from “sweating” in humid conditions. Refrigeration dryers are not suitable for installations where piping is installed in ambient temperatures below the dryer dewpoint i.e. systems with external piping.

Refrigeration dryers work by cooling the air, so are limited to positive pressure dewpoint ratings to prevent freezing of the condensed liquid. Ideal for general purpose application, they typically provide pressure dewpoints of 38°F (3°C), 45°F (7°C) or 50°F (10°C) pdp. Air is reheated before it re-enters the system to prevent piping from “sweating” in humid conditions. Refrigeration dryers are not suitable for installations where piping is installed in ambient temperatures below the dryer dewpoint i.e. systems with external piping.

Click here to watch a Parker PoleStar Smart-E Refrigeration Dryers overview video.

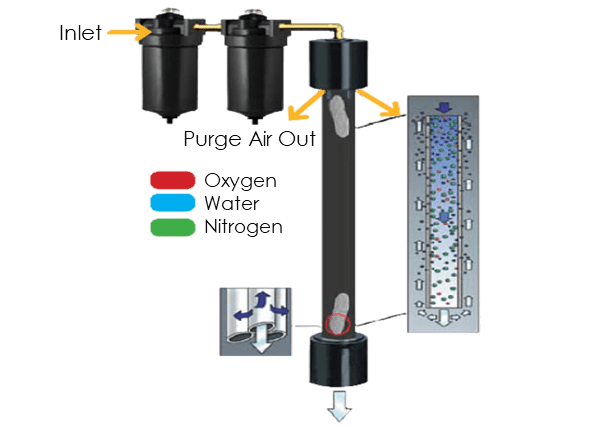

The water vapor in the compressed air is removed by the principle of selective permeation through a membrane. The membrane module consists of bundles of hollow membrane fibers, each permeable to water vapor. As the compressed air passes through the center of these fibers, water vapor permeates through the walls of the fiber. A small portion of the dry air (purge flow) is redirected along the outside of each hollow fiber, carrying away the moisture-laden air which is then exhausted to room atmosphere. The remainder of the dry air is piped to the application.

The water vapor in the compressed air is removed by the principle of selective permeation through a membrane. The membrane module consists of bundles of hollow membrane fibers, each permeable to water vapor. As the compressed air passes through the center of these fibers, water vapor permeates through the walls of the fiber. A small portion of the dry air (purge flow) is redirected along the outside of each hollow fiber, carrying away the moisture-laden air which is then exhausted to room atmosphere. The remainder of the dry air is piped to the application.